Architectural hardware has been overlooked in the move to digital construction but all that is changing with clients now demanding 3D models, certification and performance data. Daniel May of Consort Architectural Hardware examines how Building Information Modelling (BIM) is influencing modern design projects.

The future of construction is digital. What was once considered a gradual shift toward greater information management has now become a basic requirement for so many. From early-stage design through to compliance, maintenance and product lifecycle management, digital product data is no longer considered added-value – it is mandatory.

Since 2016, UK central government clients have required collaborative digital information management on centrally procured projects, commonly known as ‘BIM Level 2’. Today, these requirements are specified through the UK BIM Framework and BS EN ISO 19650 standards, setting a clear expectation that construction partners must provide accurate, structured and accessible digital information across their products.

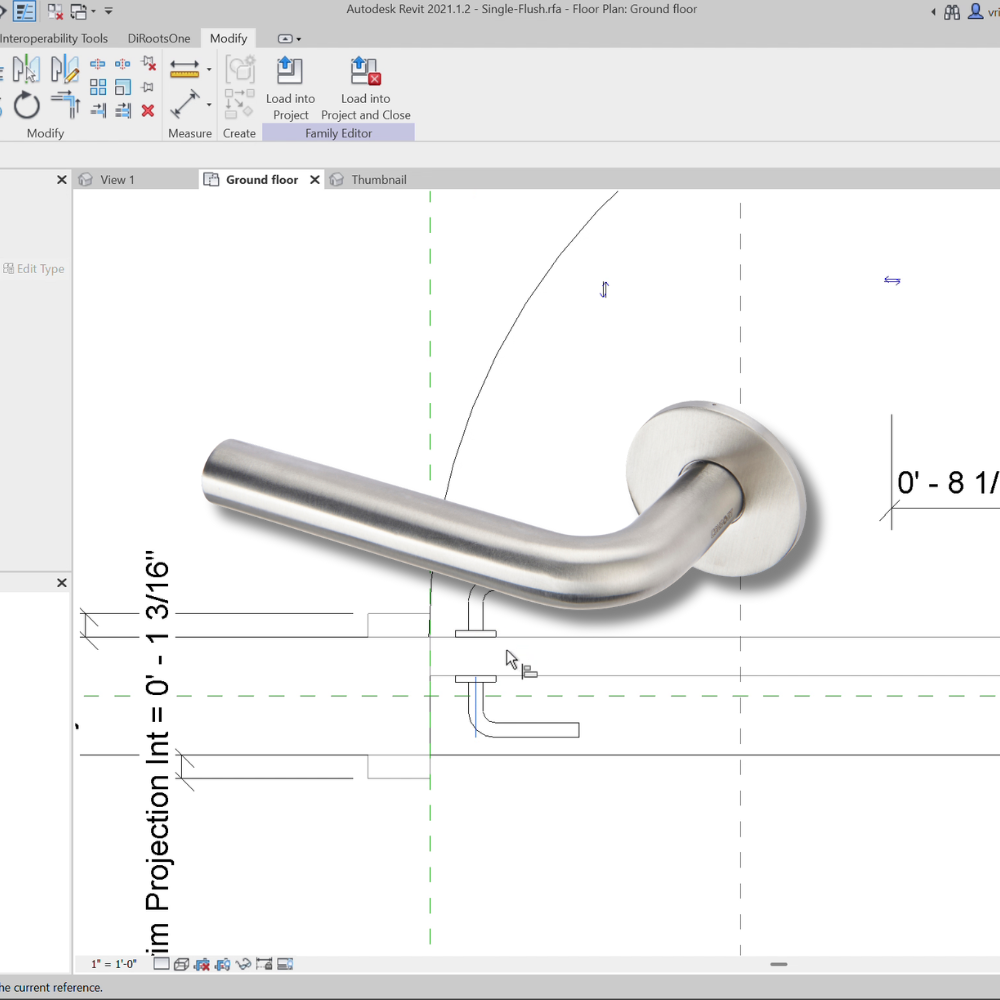

With this in mind, conscious manufacturers throughout the supply chain are enhancing their BIM capabilities, as they look to support architects, specifiers and contractors with detailed product information. Architectural hardware – traditionally overlooked in digital planning – is rapidly entering the spotlight too, with 3D models, certification and performance data now offered across a growing library of products. But how is this movement to enhanced digital resources impacting projects?

Optional to operationally clinical

Only a decade ago, building specifications relied heavily on paper resources, where professionals were limited to product brochures, PDF catalogues and basic CAD line drawings. Today, the sector is converging around fully integrated digital workflows, with teams relying on platforms such as Revit and NBS as a way of connecting design, specification, compliance and facilities management.

Digital Product Passports (DPP), soon to be mainstream and mandated by the EU, will only accelerate this trend. Though, it’s important to recognise this evolution isn’t driven by convenience alone. In fact, BIM product data now plays a central role in meeting:

- UK Government mandates for digital construction and the ‘Golden Thread of Information’

- Fire safety regulations, which increasingly require accurate, up-to-date, verifiable data

- Sustainability reporting, where Environmental Product Declarations (EPDs) and lifecycle data must be accessible at the design stage

Consequently, if a product can’t be conceptualised accurately in a digital model, it risks being excluded from a project’s specifications entirely.

BIM in architectural hardware

For some, door hardware may seem like a minor component in the grand scheme of building design and as a result, it is often overlooked as a small percentage of the project’s value. In reality, its role in safety, performance, accessibility and compliance is critical.

Fire doorsets for example, are only as effective as the hardware components that secure them. Within BIM, even a single component such as a door closer carries parametric data that can validate fire ratings, confirm accessibility and even identify potential clashes with ceiling details or door frames – helping design teams ensure both functionality and compliance are met early in the coordination process. When it comes to architectural hardware, access to reliable BIM objects enables teams to:

- Fulfil accurate design – using models with correct Level of Detail (LOD) to ensure they integrate accurately into project drawings

- Reach faster specification – architects and contractors can drag-and-drop products/objects into designs, saving hours of manual work

- Assure compliance – with product certifications, fire ratings, testing evidence and sustainability data embedded into product models

- Reduce on-site errors – accurate digital models also decrease the risk of incorrect products being installed

As digital coordination becomes routine, hardware that isn’t modelled is considered a specification risk.

Responding to new standards and digital realities

Where the tragic events of Grenfell Tower reshaped the regulatory and cultural expectations of the construction industry, the sector now faces an accelerated demand for traceable, verified product information. As new legislations continue to form, such as Martyn’s Law for example, updated guidelines will influence how public spaces are designed and secured, with each new standard placing an integral focus on resilience, traceability and responsibility in the process.

These shifts underscore a clear reality that every hardware component, no matter how small, must be backed by verifiable data and performance credentials. Conscious hardware manufacturers play a crucial role then, in supporting building safety and security by providing architects, specifiers and contractors with the confidence to select hardware that meets the standards of today and tomorrow.

And so, as we arrive in a data-driven era where compliance, traceability and efficiency are key, BIM objects have evolved from beneficial to indispensable. Whether delivering a residential high-rise, healthcare facility or a commercial development, professionals must be able to call upon trusted suppliers and their digital files as tools that help them design with confidence.

To request the full library of Consort’s BIM documentation, email [email protected] or visit Consort Architectural Hardware | Overview | NBS BIM Library for selected products.