Intumescent hardware protection on fire doors saves lives – but only if it’s designed, manufactured and installed to the highest standard, warns Mike Sutcliffe

When it comes to ensuring the safety of a building, fire protection is a top priority, particularly important in commercial and public buildings where the risk of fire can be high. One area that requires special attention is the protection of doors, especially those made from timber or composite materials.

“The importance of competence when it comes to intumescent protection kits cannot be overstated”

Mike Sutcliffe

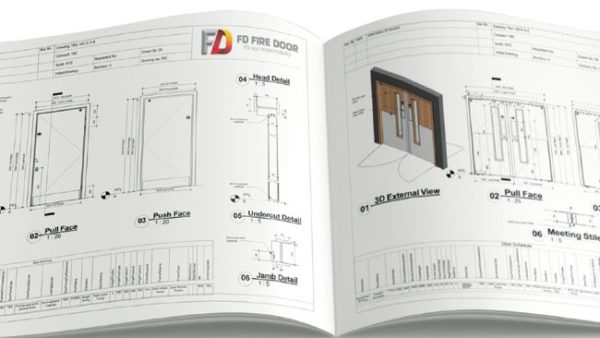

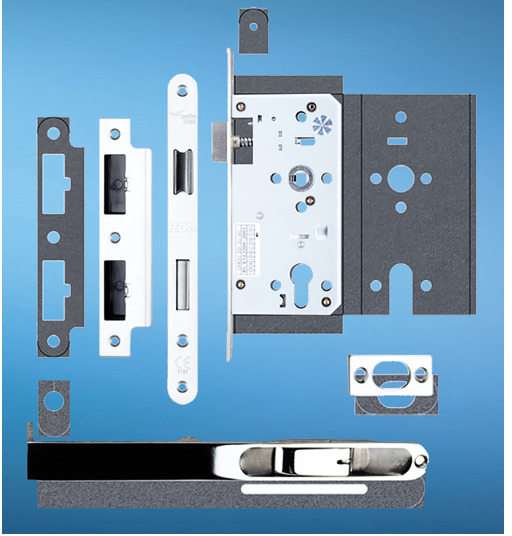

All hardware installed on timber and composite fire doors fire doors must be fitted without compromising the integrity of the assembly and this is critical where hardware such as hinges, locks and latches, flush bolts, door controls and letterplates, is rebated into the doorset.

To ensure maximum protection in the event of a fire it is essential to add intumescent protection, which greatly reduces the rate at which heat transfers through the door, expanding upon exposure to heat, preventing heat transfer on the hardware and sealing voids created during the rebating process. However, the importance of competence when it comes to intumescent protection kits cannot be overstated and their effectiveness depends on a variety of factors.

Intumescent kits should be precision engineered and designed to fit perfectly around the hardware, making them as effective as possible.

Material issues

The quality of the materials used is also crucial. Intumescent materials are not made consistently across manufacturers. For example, there is no minimum requirement for graphite content in graphite based intumescent and no maximum activation temperature, meaning seemingly identical intumescent materials can behave very differently from one another.

Buying intumescent with third party certification, which covers initial testing and includes audits to assess the consistency of production, ensures that the material will behave consistently and as stated by the manufacturer, and ensures traceability.

It’s also important to remember that even the best-designed and highest quality intumescent kit can be rendered ineffective if it is not installed correctly.

It is essential to use kits that have been developed and manufactured by companies with expertise in intumescent protection. Rebated hardware can be vulnerable and allow the spread of fire and smoke quickly, putting a building and its occupants at risk.

Intumescent protection creates a barrier around those weak points, helping to maintain the integrity of the fire door thus giving occupants of a building sufficient time to evacuate, while also helping to limit the damage caused by the fire.

Mike Sutcliffe is business development manager at Vanquish Hardware Protection