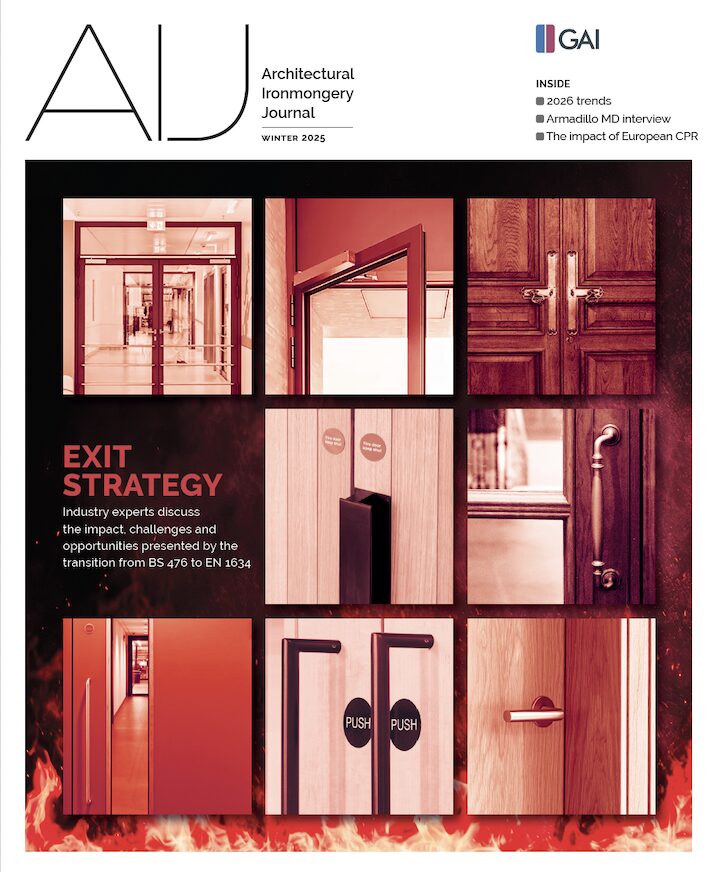

Working fire doors are a prerequisite for fire safety, but what differentiates them from regular doors? Kirk Smith offers the technical lowdown

From components and construction to features and function, there are several clear distinctions between regular doors and fire doors.

Place

Whereas regular doors are often placed throughout a building on accessibility or aesthetic merit, fire doors are strategically positioned to compartmentalise areas of the structure – such as hallways and stairwells – and are designed to help direct occupants through safe escape routes whilst also providing them with valuable time to make their way out of the building. Despite their similar appearance, regular doors are usually thinner at 35mm, while fire doors are either 44mm or 54mm thick depending on its fire rating.

Components

When opened, fire doors provide a means of escape. And when closed, they form a barrier to stop the spread of fire and smoke. To be able to do this, the main panel of the door (also known as the door leaf) is constructed from fire resistant materials that help to prevent the door from warping or collapsing when exposed to high temperatures. Nonetheless, for a fire door to become effective, it must comprise of more than just the leaf, and will include:

- The frame

- Intumescent fire – and if required for certification – smoke seals

- Glazing (although this is not necessary)

- Signage

- Door hardware, such as hinges, door closers, locks and latches

Fire doors must work in tandem with each of these components. Intumescent fire and smoke seals for example, frame the edges of the fire door and are chemically designed to expand into the frame when exposed to temperatures beyond 200°C. In doing so, the seals close the gaps between the frame and the door itself, eliminating any possibility of fire – and if required, smoke – from passing through.

Operation

From an operational viewpoint, fire doors work differently than regular doors too. Fire door hardware is indispensable to fully operational doorsets, where during a fire incident, an open door is rendered useless. To be able to form an effective barrier against fire, a door must close to completion from its open position, and as part of this process, it will call upon its hinges, locks, latches and door closing devices. Door closers, whether concealed or surface-mounted, use spring-loaded hydraulics to effectively close and engage the door into its latch, where it is held firmly in place by the frame, whereas regular doors rely on manual control.

For buildings with high footfall, an electromagnetic hold-open device may be present on a doorset. These systems are permitted to keep certain fire doors open until a fire alarm is activated, aiding ease of movement until the first sign of a fire incident, in which the system will automatically release and close the doors to completion. Equally, panic and emergency exit devices can be found on some fire doors that are positioned throughout a building’s escape routes.

Testing and standards

To certify fire performance, the complete fire doorset is put through periods of standardised destructive testing in accredited laboratories and workshops. The standard fire performance test method complies to EN 1634-1, and in conjunction with product standard EN 16034, it provides the supply chain with manufacturing guidelines, and as a result, gives responsible persons and end users peace of mind that their doorset will function in a fire scenario.

Fire doors are a legal requirement in all non-domestic properties and houses of multiple occupancy and with updated fire safety regulations now in effect, third-party testing and product traceability is as crucial as ever. Upon testing, certified fire doors are given a fire-resistance rating which details the length of time the door and its hardware components can withstand fire and smoke, with the most common FD ratings being FD30 and FD60, which declare the doorset can withstand fire for 30 or 60 minutes respectively, and FD30S and FD60S if the doors have been tested with smoke control. A regular door with no fire-resistance characteristics would not be able to withstand these tests and as such, would fail in a real-life event.

What’s more, fire resistance tests are conducted on representative samples, and as such, components should not be substituted post-specification and installation. Fire door hardware for example, in addition to rigorous fire safety testing, must go through stages of performance testing to ensure it functions properly and is able to sustain a level of durability that makes them fit for purpose.

Mechanical controlled door closers must be tested to the appropriate standard EN 1154, which classifies hardware over its category of use, number of test cycles, power size, fire behaviour, safety and corrosion resistance. Equally, emergency exit devices and panic exit devices are tested to EN 179 and EN 1125 respectively and electromagnetic hold-open devices to EN 1155. A fire door’s single axis hinges must also be must also be tested to EN 1935.

Kirk Smith is national sales manager at Allegion.