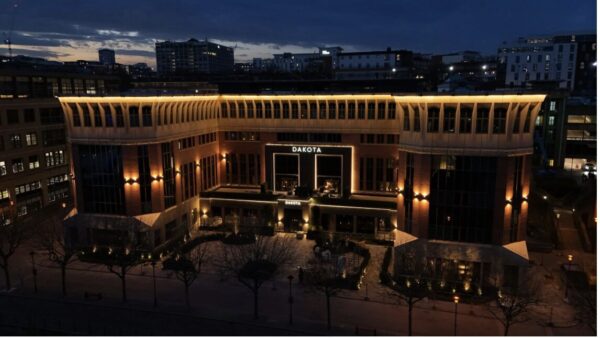

Architectural ironmongers HAF @ John Planck Ltd and EPR Architects received a total of three awards for their work together on the Grade II listed Old War Office in Whitehall at the recent RIBA/GAI Specification Awards.

The team scooped the Hospitality Award for the Raffles London at OWO project, the Residential Award for The Old War Office Residences and claimed the top prize of Winner of Winners, sponsored by GEZE. The project impressed the judges with its “huge amount of beautifully crafted bespoke ironmongery which fits seamlessly into the overall aesthetic of the building”. They commented on the attention to detail in the specification calling it “exceptional”.

Originally built in 1906, the Edwardian building is steeped in history including its role as a command base for Winston Churchill during World War 2. The London landmark was sensitively restored over an eight -year period (2015-2023) and transformed into a five star hotel and luxury residences. Raffles has taken residence at The OWO with its first UK hotel in a collaboration with New York-based designer, Thierry Despont. This architectural gem is now fully open to the public, with the hotel, 85 unique private residences, nine restaurants, three bars, Guerlain’s first London Spa.

HAF@John Planck Ltd was approached by EPR Architects, the lead architect, to assist with scheduling the ironmongery for the entire project – both residential’ and the Hotel – with over 5,300 doors and 1,000 windows, spread across 19 separate packages.

“Co-ordination was vital to the success of this project,” say the ironmongers. “We liaised with a staggering 37 different consultants including four separately appointed interior designers for the numerous areas across the entire project, ensuring suitability and compliance of the ironmongery design intent throughout.

“This co-ordination included our own supply chain, predominantly UK based, but also further extended to the various door manufacturers appointed to the project who we worked closely with to ensure the ironmongery proposed was suitable and compatible for the vast amount of differing door types and designs.”

The restoration of such an iconic landmark required a fully co-ordinated range of ironmongery suitably performance and fire tested to meet the requirements of the existing and new doors throughout the development.

With a total number of different product types supplied in the hundreds, the number of differing bespoke products designed and manufactured was well into double figures ranging from lever handles, pull handles and other door trim items to window and espagnolette handles and other general accessories.

Primarily because of the Covid-19 outbreak, there was a client request for a protective coating to be applied to the common area fittings including the outside of the hotel bedroom doors, that are handled in order to protect the guests from ongoing and future infectious diseases.

“We applied a Nanotech coating which is a titanium oxide that exhibits strong oxidative properties capable of decomposing harmful organic compounds, killing bacteria as well as eliminating odours when exposed to light,” says the ironmongers.

In addition to the ironmongery, HAF@John Planck also supplied, installed and commissioned over 50 automatic door operators throughout with push button and key switch activation based on the client’s requirements. Instead of finger protection devices running vertically for the majority of the door heights, it specified ‘flat scan’ 3D laser safety sensors. The high-resolution volumetric laser curtain detects fingers and bodies in the entire detection area, allowing perfect safety of the hinge zone with coverage of the leading edge to safeguard this part of the door too.

The protective ‘Nanotech’ coating was used on the push to exit buttons and key switches for the auto door operators.

Given the number and variety of architects door designs, sizes, construction and ironmongery requirements, every door type was outside of the door manufacturer’s standard test scope, so each type was independently fire tested (over 50 in total) at a cost of circa £500,000. HAF supplied over £100,000 of sacrificial ironmongery to be burnt as part of each test with over £1,200,000 worth of door leaves tested and burnt during the course of the project.

As with the hotel, brass was used as the base material of the trim furniture with a mixture of burnished bronze and antique brass finishes chosen to develop a natural patina over the course of time where possible.

The lever furniture was bespoke manufactured based on an Art Deco design concept with stepped detailing to the tapered neck and face of the lever handle grip with a matching step to the rosette. Ancillary items such as escutcheons and bathroom turn/releases were also produced, consistent with the stepped detail.

For the entrance doors, bespoke centre door knobs and bell pushes were produced and for the sliding pocket door systems that were used in ‘latch’ and ‘bathroom’ scenarios, we manufactured bespoke ‘plain’ and ‘bathroom’ flush pulls, all machined with the stepped detail design to compliment the trim furniture.

This design followed on to the custom floor door stops which had the stepped detail machined into the top surface area.

Even the bespoke casement lever handles that were produced to operate the espagnolettes, some with a euro-profile cylinder cut-out at the correct ‘centres’, had the stepped design detail to the backplate to coordinate with the door ironmongery.

All of this and the relevant corresponding sash lifts, fasteners, stops and screws were all finished in the burnished bronze finish to stay in keeping with the aesthetic theme.

However, a further challenge was with regards to other products produced from alternative materials that were required to be specially refinished to be as close a match as possible to the burnished bronze finish. Items such as the mortice electric locks, automatic door operator covers and arms, anza bolts, ‘push to exit’ buttons and key switches were all successfully re-finished, with the buttons and key switches being done prior to the application of the Nanotech protective coating.

“Monumental is the only adjective to describe an undertaking that transforms 580,000 sq ft of former government offices into 750,000 sq ft of luxury residences and some of the most expensive hotel suites in Europe!”