Russell Smith technical manager at Mann McGowan asks when it comes to ironmongery and the intumescent, who is ultimately responsible for ensuring that both components are suitably matched, specified and installed?

We all know the importance of the interaction between ironmongery and the intumescent, but who is ultimately responsible for ensuring that both components are suitably matched, specified and installed?

Once the architectural practice has produced the required specification the job will go out to competitive tender and perhaps this becomes the first hurdle: what do you include or leave out to make sure your tender is ‘competitive’?

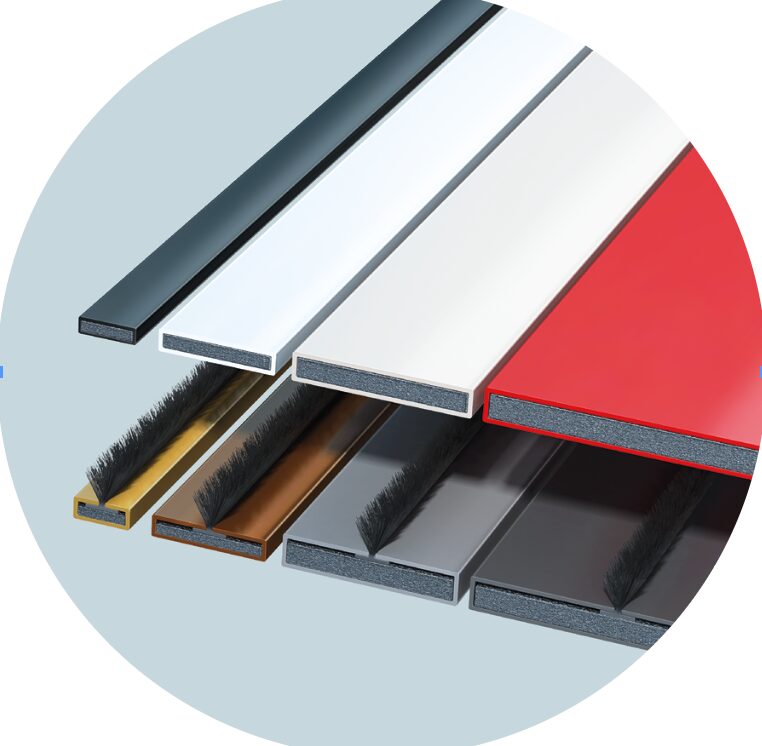

If the architectural ironmonger completes a full and detailed schedule this will not only include the specified hardware but also allow for additional items. These items include intumescent pads and wraps that may form part of the fire test evidence for the specified hinges, lock sets, concealed closing devices, letterplates and spy viewers for example, all of which can fall within the category of needing intumescent to meet the requirements of the fire test evidence. The question raised is then: does this keep us competitive or do we exclude these items and trust that the door set manufacturer will allow for the ironmongery protection intumescent within its quotation?

If the door manufacturer holds suitable fire test evidence to support the specified doorset including the ironmongery suite the architect has specified, then at this stage they could swap out the intumescent protection as dictated by the fire test evidence they hold, and this would still allow for a fire tested solution to be delivered to site. The doorset manufacturer takes responsibility for the overall package and the ironmonger loses a chunk of income from the tender.

If the door manufacturer cannot provide this evidence, then they are reliant on bringing in the required ironmongery suite along with the appropriate intumescent protection. At the tender stage the ironmonger must have had to correctly match the two items together to know that suitable evidence allowed for the specified items to be used together or to flag up inconsistencies and put forward alternatives that would provide the required level of fire resistance.

Trying to keep within the guidelines of ‘good practice’ and maintaining a level playing field becomes very challenging. We all know how time consuming the tender process is and the poential pitfalls that happen: value engineering and breaking specifications are probably high up the list when your tender is unsuccessful.

Being an intumescent seal manufacturer and supplier, we are removed from the tender stage but still need to provide cost effective and fire tested components to support the ironmonger in today’s marketplace.