David, you’re six months into your role as MD. How are things going?

The first six months at Vanquish have been very challenging but hugely rewarding and I’m really enjoying it. I’m pleased to say that we’ve hit the ground running and

that’s certainly been helped by the incredible team.

We’ve been able to streamline several of our processes, enhance our production efficiency, and strengthen relationships with key partners. We’ve been carrying out building works to accommodate our investments in new machinery, most notably a new sheet extrusion line to run our graphite materials as well as additional cutting technologies to the conversion side.

We’ve also strengthened the team and made some key appointments, including a new operations manager, a warehouse supervisor and some team leader promotions internally. It’s been an intense period but I’m confident that we are on course to achieve our strategic goals this year.

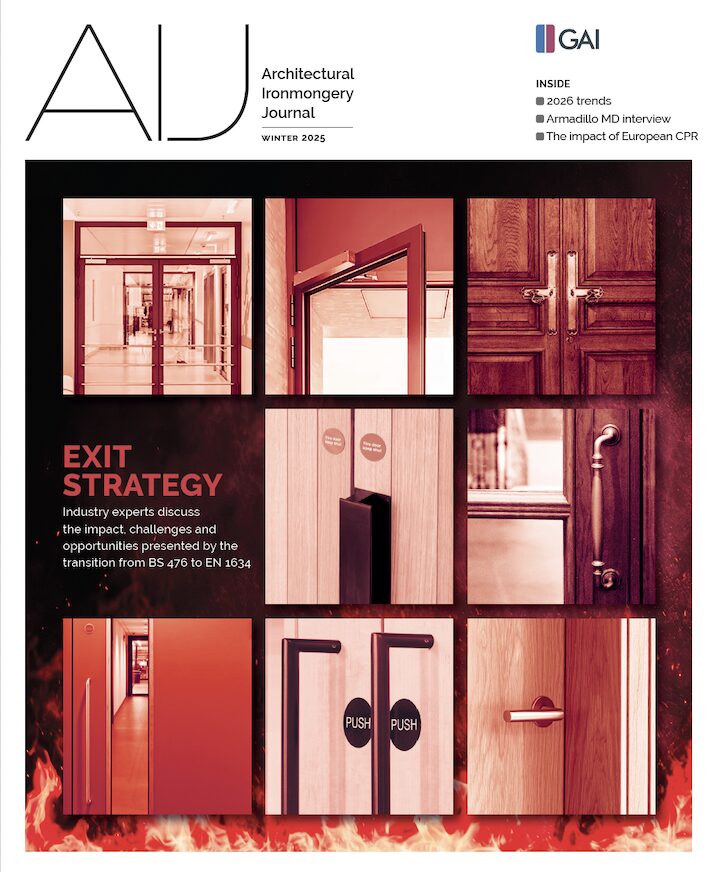

The game has changed for ‘fire products’; how has your business had to adapt?

The government has recently announced it will abolish the national classes for fire testing (BS 476 – Fire tests on building materials and structures). Fire doors tested in England have historically been tested BS 476 Part 22. This will now be replaced with EN 1634:1 which is seen by many as a more robust testing method and is also known to be more onerous than the BS 476:22 test. This will have a huge knock-on effect on the fire door industry, including the increased need for intumescent hardware protection as it is almost always needed on rebated hardware tested to EN 1634:1. With this in mind we have increased our production capacity by 30%.

We have also seen an increase in customers who wish to see third-party accredited products, this offers peace of mind to clients as they can be sure they are purchasing a consistent product that will perform to the specification.

We’ve spent a lot of time and money in research and development of new intumescent compounds that are higher performing, have increased fire-retardants, and a stronger resultant char. This means our products can be used in a greater variety of applications and Vanquish is now becoming a one-stop-shop for intumescent solutions. Due to this, we are confident that we can expand our product range to other passive fire protection products and do not have to focus solely on the fire doorset market.

Training and education has always been key for Vanquish too, hasn’t it?

We believe that education is vital to ensuring compliance within the passive fire protection market. Unfortunately, we still encounter people who do not understand our products or do not think they are essential components for fire doorsets.

To combat this, we have been working closely with the GAI, IFSA, and other industry bodies to inform the end user of the importance of hardware protection.

At the time of your appointment, you mentioned intentions to innovate. Can you tell us more?

Innovation is a big part of what we do at Vanquish. We’ve launched several initiatives to drive product innovation and improve our services. We’re exploring further new and improved materials and technologies to make our intumescent products and offerings even better and we’re particularly interested in creating more eco-friendly hardware protection that meets safety standards and supports sustainability.

We’ve also invested in a new MRP (Material Requirements Planning) system to streamline our production, reduce waste, and boost efficiency. These innovations, along with our new cutting technologies and the building upgrades are setting us up for a bright future and I’m really excited with the direction the business is going in.

What else is a key focus for Vanquish right now?

Right now, a key focus for us is expanding our market presence and reinforcing our reputation as a leader in hardware protection. We’re working on growing our distribution network to reach new markets both in the UK and abroad.

Customer satisfaction remains a top priority, of course, so we’re enhancing our customer service to provide more responsive and personalised support. I truly believe in partnering with our customers and to enhance their product ranges and bring additional benefits wherever possible.

Investing in our people is also crucial, as they are at the core of the business. We’re committed to ongoing professional development to ensure our team has the skills and knowledge to drive us forward. This combined with everything else is a part of our broader strategy to meet growing customer demands more efficiently.